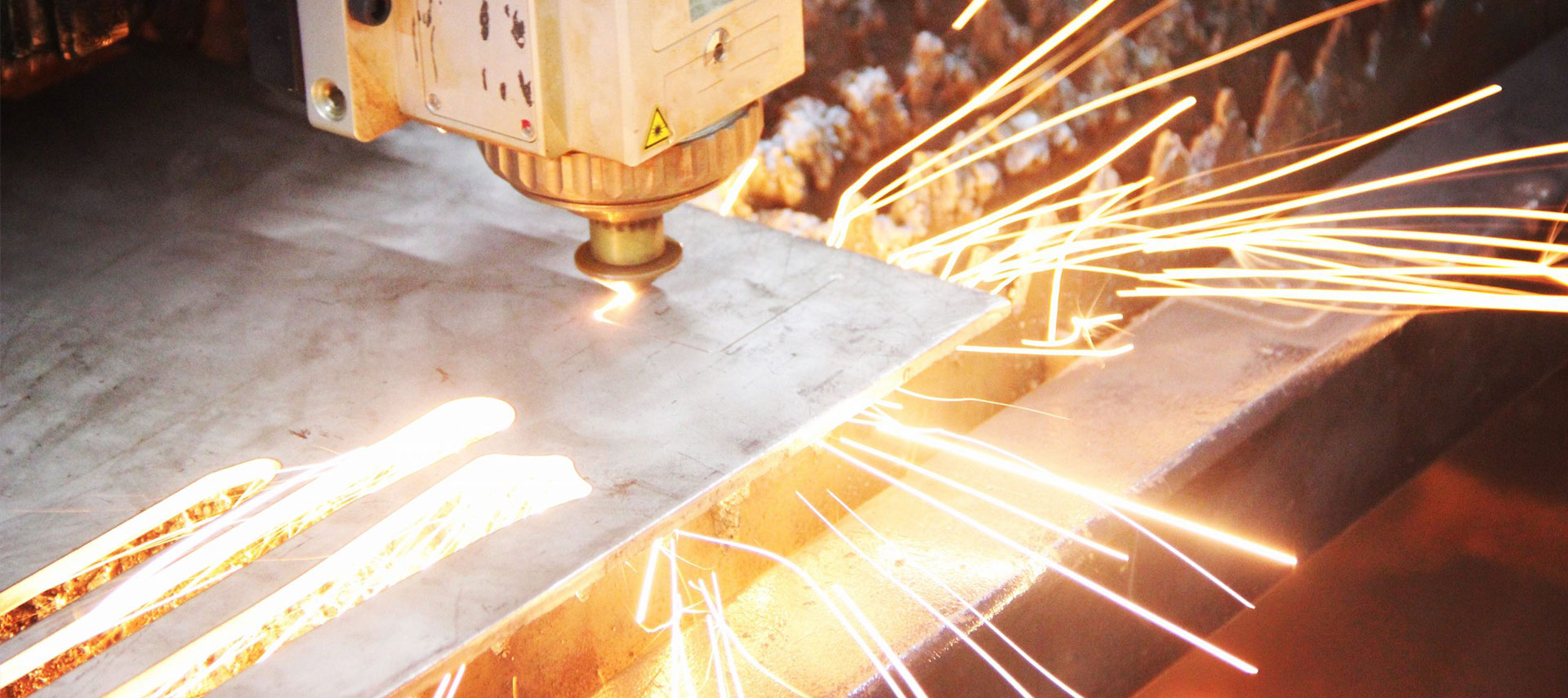

Suzhou Shinetek grinding technology co., LTD. was established in 2014, focusing on the development and application of flexible grinding technology, it provides solution to those issues found in existing metal grinding processes where intensive labor were required but resulted in low quality and low efficiency as well as high pollution to the environment. It will largely improve your production efficiency and quality while reducing the manufacturing cost and protecting the environment simultaneously. In years of development, we successfully developed serial automation products covering different functions to meet various customer's demands, such as deburring, removing the slag and oxidation layer, brushing the hair line, and polishing etc.

-

2014

Was established

-

1000+

Well-known customers worldwide

-

20+

R&D engineer

-

16

Certificate of honor patent